Cold rolled steel sheet & plate

Cold rolling is a steel sheet rolled to a target thickness at room temperature below the recrystallization temperature. Compared with hot-rolled steel, the thickness of cold-rolled steel is more accurate, and the surface is smooth and beautiful.

Key words:

classification:

Steel Plate & Coil

Hotline:

Cold rolled steel sheet & plate

Cold rolling is a steel sheet rolled to a target thickness at room temperature below the recrystallization temperature. Compared with hot-rolled steel, the thickness of cold-rolled steel is more accurate, and the surface is smooth and beautiful.

Cold-rolled steel sheets use hot-rolled steel coils as raw materials. After pickling to remove the oxide scale, they are cold-rolled. The finished product is hard-rolled coils. Cold work hardening caused by continuous cold deformation increases the strength, hardness and toughness of the hard-rolled coils. The plastic index drops, so the stamping performance will deteriorate, and it can only be used for simple deformed parts. Hard rolled coils can be used as raw materials for hot-dip galvanizing plants, because the hot-dip galvanizing lines are equipped with annealing lines. The weight of the rolled hard coil is generally 6 to 13.5 tons, and the steel coil is continuously rolled on the hot-rolled pickled coil at room temperature. The inner diameter is 610mm.

Features:

Because it has not been annealed, its hardness is very high (HRB is greater than 90), and its machining performance is extremely poor. It can only be used for simple directional bending of less than 90 degrees.

To put it simply, cold-rolled steel sheets are processed and rolled on the basis of hot-rolled coils. Generally speaking, it is a process of hot rolling-pickling-cold rolling.

Although the cold-rolled steel sheet will heat up due to rolling during the processing process, it is still called cold rolling. Because hot rolling is cold rolled after continuous cold deformation, the mechanical properties are relatively poor and the hardness is too high. It must be annealed to restore its mechanical properties, and those without annealing are called rolled hard coils. Rolled hard coils are generally used to make products without bending or stretching.

previous page

next page

previous page

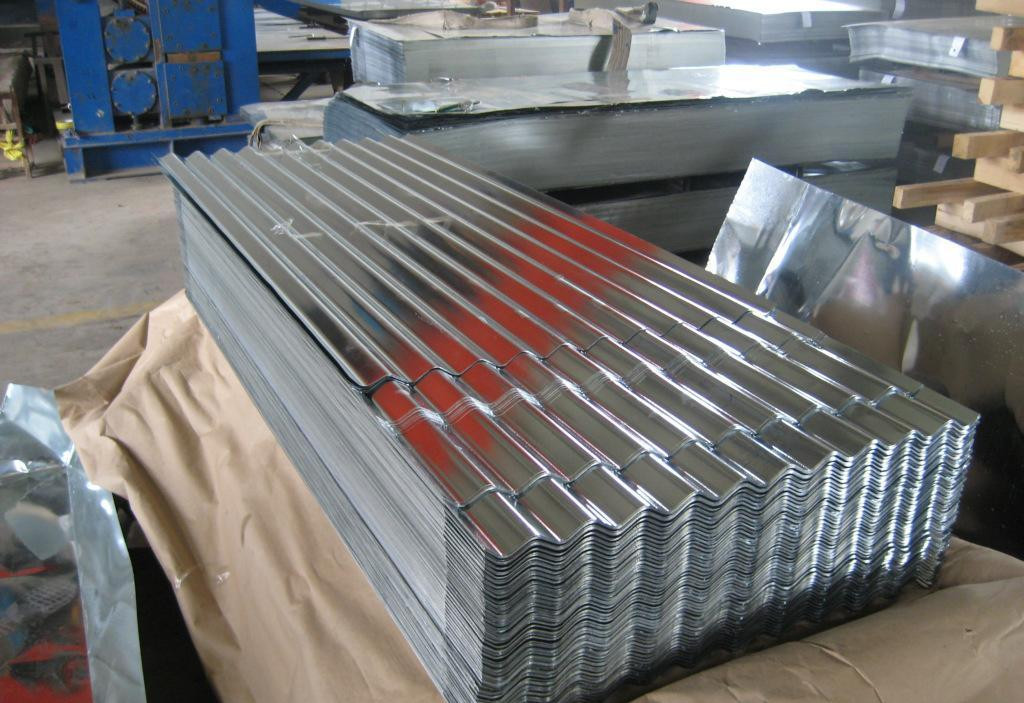

Corrugated roofing steel sheet

next page

Related Products